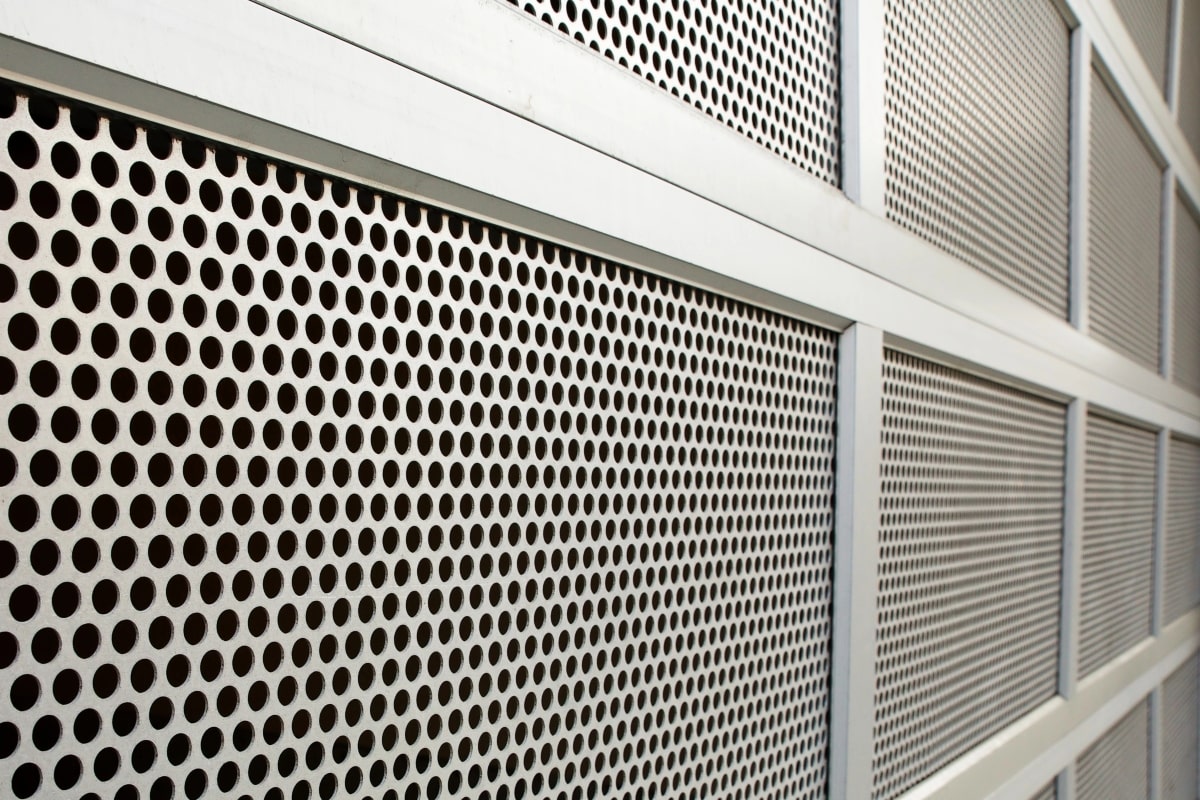

Perforated metal is a versatile material with broad functionality and beautiful aesthetics. This fantastic material is utilised by various industries, from architecture and manufacturing to construction and security. Perforated metal is ideal for security screens and doors, as it provides practical benefits and looks impressive in contemporary settings.

This article will highlight the many applications and benefits of perforated metal. By the end, you’ll understand why it’s the preferred option for security doors and screens.

What is perforated metal?

Perforated metal refers to metal sheets that have been mechanically or manually altered. The original material is commonly aluminium but can also be stainless or galvanised steel.

This metal is punched, stamped, or cut with different patterns based on the intended application. Perforated metals are produced with holes, slots, or decorative designs, transforming the original solid material into a robust, lightweight end product.

Perforated metal augments the structural integrity of the source material with greater flexibility and more design options. This gives it a wider range of commercial and residential applications. With lightness, durability, and visual appeal, perforated metal is ideal for security screens, ventilation systems, and architectural elements.

How are perforated metal sheets made?

The manufacturing process for perforated metal involves several precise techniques, with the following methods being the most common:

Punching

Flat sheets are fed into a punch press fitted with a die during this process. The die then punches holes into the sheet in a pre-set pattern. Punching is ideal for simple, repetitive designs, such as those used in ventilation panels or industrial filters.

Stamping

Stamping uses a press to create more complex shapes and patterns. This method is particularly effective for thin sheets of aluminium and other lightweight metals, especially in decorative applications.

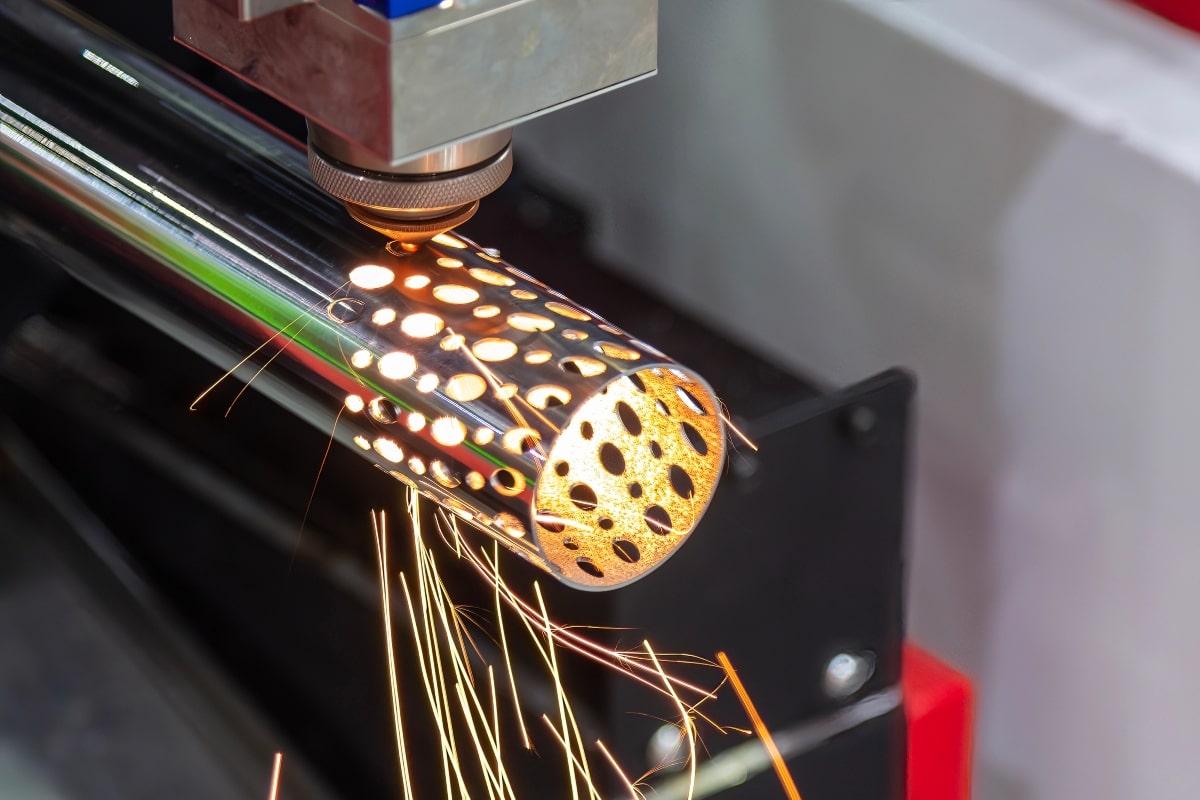

Laser cutting

For high-precision perforations, laser cutting is often the preferred technique. Manufacturers can create intricate and custom patterns with exceptional accuracy using computer-controlled lasers.

Customisation options

Along with the quality of the source material and the variety of production methods, perforated metal is also highly customisable. Manufacturers can tailor the perforation size, pattern, and material to suit specific needs. For example, security screens can be created with small, dense holes for added strength and design appeal.

Materials used in perforated metals

The choice of material plays a crucial role in the final product’s performance, durability, and cost. Like always, the final choice depends on several factors, from cost and durability to aesthetic preferences and intended applications. Common materials include:

Aluminium

Aluminium can be found across the built environment. This lightweight material is non-corrosive and easy to work with, making it ideal for applications like security screens, facades, and decorative door panels.

Aluminium perforated metal sheet is a low-maintenance option, as it’s easy to clean and rust-resistant in outdoor settings.

Stainless steel

Known for its strength and anti-corrosive properties, stainless steel is widely used in external applications. When durability is paramount, stainless steel is often the preferred choice. Perforated steel sheet metal is well-suited to security doors and screens, especially in areas prone to harsh weather.

Galvanised steel

Galvanised steel is a popular material with various potential applications, especially in commercial and industrial settings. It’s been coated with a layer of zinc to enhance corrosion resistance. This material is ideal for public spaces and other locations that demand longevity and low maintenance.

Other metals

The three materials listed above are responsible for most commercial perforated metal products. However, other materials can also be used for highly specialised applications or particular aesthetics.

Examples include brass, copper, and carbon steel. These metals have a unique visual appeal, which makes them popular in artistic installations and custom interiors.

Applications of perforated metal

The versatility of perforated metal makes it indispensable in the modern world. This material is used across various domains, including the following popular applications:

Security and privacy

Security screens for doors and windows

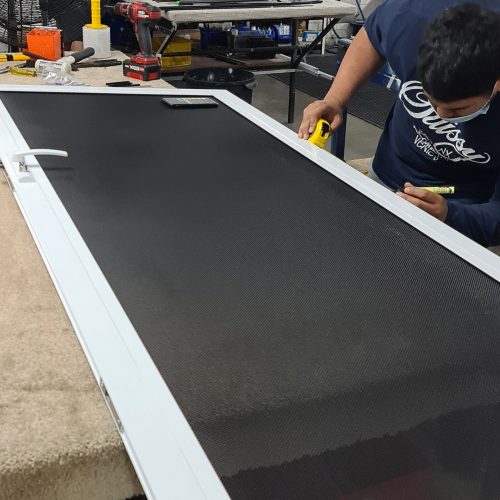

Perforated metal is a popular choice for security screens and doors, offering a combination of strength, durability, and modern aesthetics. Products like IntrudaGuard® are made from a single sheet of marine-grade aluminium, making them highly durable and corrosion-resistant.

Designed for both performance and style, IntrudaGuard® features a unique, patented bonding process that eliminates the need for unsightly fixings, ensuring a clean, seamless appearance. These security screens provide excellent ventilation, robust protection, and easy maintenance, making them an ideal choice for homes and businesses seeking a blend of functionality and design.

Privacy screens

For outdoor spaces, perforated metal is ideal for privacy screens. Durable and stylish outdoor patio screens offer privacy from neighbours and reduce noise. Decorative screens feature intricate patterns that filter natural light. They are also ideal for creating green walls and supporting living plants.

Architecture and design

Architecture frequently uses perforated sheet metal for facades, ceilings, partitions, and sunshades. It has a unique ability to balance aesthetics with functionality. This allows architects to create visually stunning designs while improving energy efficiency, ventilation, and light management.

Industrial and functional

Perforated metal sheets have numerous industrial applications. Along with security products, it’s used to create noise and privacy barriers, ventilation systems, commercial filters, and industrial sieves. It helps to control airflow and sound transmission, which makes it essential in manufacturing and infrastructure projects.

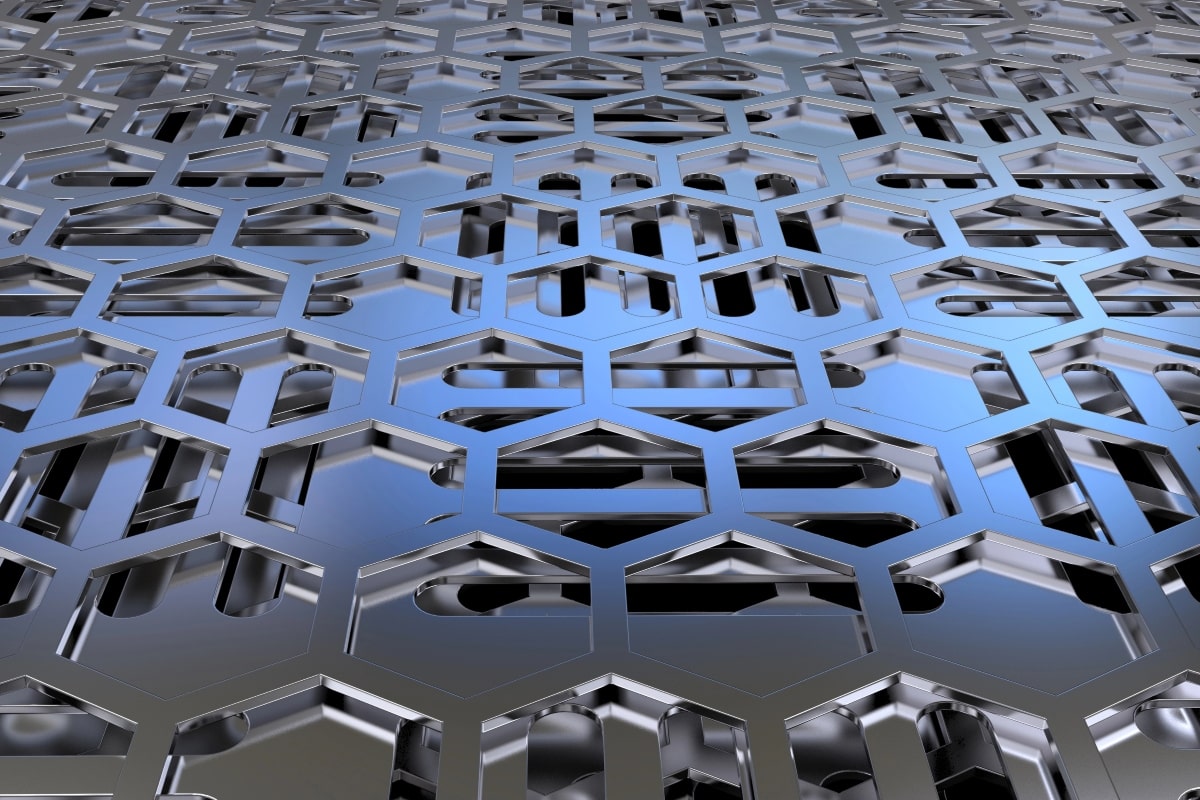

Decorative and creative

Artists and designers use perforated sheet metal for aesthetic reasons. From one-off installations to furniture and home decor, it has a unique visual appeal that resonates perfectly with modern design themes. Perforated metal allows for deep customisation, with customers able to select intricate patterns for their space.

Benefits of perforated metal

Perforated metal sheets offer various benefits for industrial, commercial, and residential use cases. The following advantages are among the most important:

- Physical properties: This functional metal has excellent structural integrity, strength, long-term durability, and corrosion resistance. Perforated metal can withstand a range of environmental and mechanical stresses.

- Functional advantages: Perforated metal screens also have functional benefits. It’s ideal for many environments, from sound absorption to light filtration and air ventilation.

- Aesthetic benefits: With outstanding design versatility, this material will seamlessly blend into any space. Metal materials can be perforated in various designs to match any setting.

Types of perforated metal

Perforated metal is available in various types, making it suitable for creating security screens and doors in various shapes and sizes. Options range from the choice of source material, such as aluminium or steel, to the finished dimensions and design patterns, ensuring a solution for every need.

The following options determine the form and functionality of perforated metal products:

- Hole sizes and patterns: Common perforated patterns include round, square, and hexagon. Custom products add unique decorative patterns or design elements.

- Thickness and gauge: The thickness of the sheet influences its strength. Security screens typically use thicker metal for enhanced protection.

- Perforation density and openness: The open area ratio to solid surface impacts transparency, airflow, and structural integrity. There can be a trade-off between strength and ventilation.

Selecting perforated metal for security screens and doors

When choosing perforated metal for security applications, there are many things to consider. Material selection is a primary concern, with metals differing in strength, durability, and weather resistance. Design considerations are also key, with great designs that balance aesthetics and functionality while meeting Australian Standard AS 5039.

Make a statement with perforated metal screens

For a secure and stylish home, IntrudaGuard® security screens are an excellent choice. Combining durability, functionality, and modern design, Amplimesh® security screens are visually appealing and defend against intruders.

Explore our range of security screen doors and windows, or contact the experts at Central Screens & Locks today.